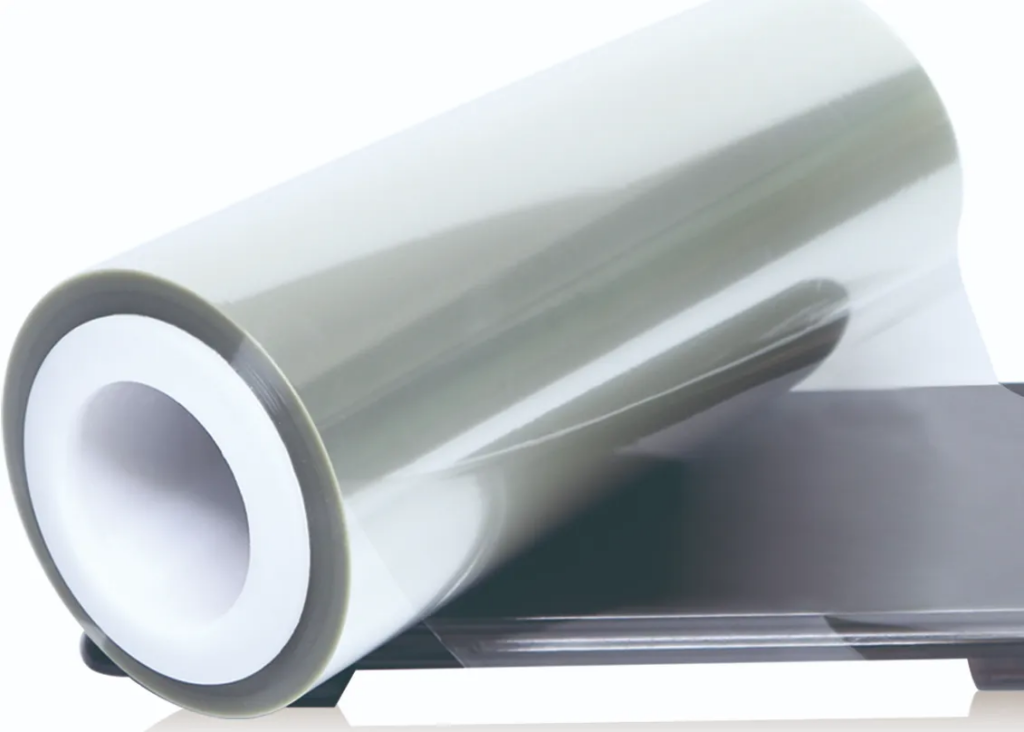

RIGID PVC FILMS

We offer a wide range of Rigid PVC Film for Pharmaceutical Blister Packaging. Rigid PVC Films are suitable for both rotary and flatbed blister packing machine.

Our range includes clear, coloured and metallised Rigid PVC Films in thickness range of 150 – 600 microns.

The most commonly used specifications are PVC : 250 micron & 300 micron clear/coloured.

CUSTOMISATION AVAILABLE: –

- Printing on PVC film

PVDC COATED PVC FILMS

This layer of additional coating is to maximise the shelf life of the product as it reduces the impact of oxygen and water vapour on the final product. PVdC coated films can give a high gloss or metallic finish to the product.

Prime Features: –

- Heat Sealable both the sides

- Excellent resistance to water, gases and other smells

Most commonly used specifications of PVdC Coated PVC: –

- PVC / PVdC : 250 micron PVC /40 gsm PVdC

- PVC / PVdC : 250 micron PVC /60 gsm PVdC

- PVC / PVdC : 250 micron PVC /90 gsm PVdC

- PVC / PVdC : 300 micron PVC /40 gsm PVdC

- PVC / PVdC : 300 micron PVC /60 gsm PVdC

CUSTOMISATION AVAILABLE: –

- Printing on PVdC coated PVC Films

COLDFORM

Cold Forming Films or more commonly know as Alu-Alu is a metallised film developed to give good barrier properties. These films have: –

- Heat Sealable on the PVC side.

- Excellent resistance to water, gases and other smells.

Most commonly used specifications of Cold Forming Films: –

- oPA/ALU/PVC : 25 micron oPA /45 micron ALU / 60 micron PVC

- oPA/ALU/PVC : 25 micron oPA /50 micron ALU / 60 micron PVC

CUSTOMISATION AVAILABLE: –

- Printing on Cold Forming Films

ULTRA-GRADE BARRIER FILMS

Ultra Grade Barrier Films are all speciality in-house films designed to maximise shelf life of the end-consumer products.

These films have excellent water vapour barrier and O2 barrier.

Prime Features:

- Heat Sealable both the sides

- Excellent resistance to water, gases and other smells.